Alloy Steel Pipe

-

Introduction

- Alloy Steel Pipes & Tubes SpecificationPipes Size : 1 / 8NB TO 26NB IN

Tubes Size : 1 / 2” OD up to 5” OD, customs diameters also available

Specifications : ASTM A / ASME SA335, A213, A691

Standard : ASTM, ASME and API

Length : Single Random, Double Random & Required Length

Outer Diameter : 6-2500mm; WT:1-200mm

Thickness : 0.3mm – 50 mm

Schedule : SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Types : Seamless / EFW / Fabricated

Form : Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes

End : Plain End, Beveled End, Treaded

Grades : ASTM A335 Gr. P5, P9, P11, P12, P21, P22 & P91, ASTM A213 – T5, T9, T11, T12, T22, T91, ASTM A691.

Standard Specification for Alloy Steel Pipes

ASTM A335 / A335M - Standard Specification for Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service

ASTM A691 / A691M - Standard Specification for Carbon and Alloy Steel Pipe, Electric-Fusion-Welded for High-Pressure Service at High Temperatures

ASTM A999 / A999M - Standard Specification for General Requirements for Alloy and Stainless Steel Pipe

ASTM A369 / A369M - Standard Specification for Carbon and Ferritic Alloy Steel Forged and Bored Pipe for High-Temperature Service

ASTM A426 / A426M - Standard Specification for Centrifugally Cast Ferritic Alloy Steel Pipe for High-Temperature Service

Applications

Pipes for Engineering purpose

Pipe Line for Gas & Water

Paper Mill Equipment

Petroleum Refining — recuperators, catalytic recovery systems

Power Generation — tube hangers, pulverized coal burners

Thermal, Nuclear and Solar Power Plants

Petrochemicals and Refineries

Oil & Gas Exploration

Features

Corrosion resistant

Durable functioning

Malleable

Heat resistance

High strength

Excellent conductivity

Impeccable finish

Enhanced service life

Precisely designed

Specification

-

- Size:

Alloy Steel Pipe Types Out diameter Wall thickness Length NB Sizes (in stock) 1/8” ~ 8” SCH 5 / SCH 10 / SCH 40 / SCH 80 / SCH 160 Upto 6 Meters Alloy Steel Seamless Pipe (Custom Sizes) 5.0mm ~ 203.2mm As per requirement Upto 6 Meters Alloy Steel Welded Pipe (in Stock + Custom Sizes) 5.0mm ~ 1219.2mm 1.0 ~ 15.0 mm Upto 6 Meters Alloy Steel Tube

Grade Temper Specification 4130 N MILT6736, AMS6360, AMS6371 4140 A, N, T AMS6381 15CDV6 T980, T1080 AIR9160C, 1.7734.5, 1.7734.6 Alloy Steel Pipe

Size" MSL Make ISMT make JSL Make 1/2"2,058.822,051.472,066.183/4"1,838.241,830.881,845.591"1,691.181,683.821,698.531.25"1,647.061,639.711,654.411.5"1,544.121,536.761,551.47Alloy Steel Pipe Pressure Rating

Maximum working pressure of Welded Alloy Steel Pipes at temperature 400°F

Maximum Allowable Pressure (psi) NPS Outside Diameter Schedule (in) (in) 10 20 30 STD 40 60 XS 80 100 120 140 160 XXS 1/4 0.54 7985 7985 10798 10798 3/8 0.675 6606 6606 9147 9147 1/2 0.84 6358 6358 8575 8575 10908 17150 3/4 1.05 5273 5273 7187 7187 10220 14373 1 1.315 4956 4956 6670 6670 9316 13340 1 1/4 1.66 4133 4133 5638 5638 7380 11276 1 1/2 1.9 3739 3739 5158 5158 7247 10316 2 2.375 3177 3177 4498 4498 7097 8995 2 1/2 2.875 3460 3460 4704 4704 6391 9408 3 3.5 3024 3024 4200 4200 6132 8400 3 1/2 4 2769 2769 3896 3896 4 4.5 2581 2581 3670 3670 4769 5782 7339 5 5.563 2273 2273 3303 3303 4404 5505 6606 6 6.625 2071 2071 3195 3195 4157 5318 6390 8 8.625 1420 1574 1829 1829 2307 2841 2841 3375 4085 4613 5147 4971 10 10.75 1140 1399 1664 1664 2279 2279 2708 3277 3847 4558 5128 4558 12 12.75 961 1268 1441 1560 2160 1922 2644 3244 3843 4324 5042 3843 14 14 875 1092 1313 1313 1533 2079 1750 2625 3283 3829 4375 4921 16 16 766 956 1148 1148 1531 2009 1531 2585 3157 3733 4404 4882 18 18 681 849 1192 1021 1530 2042 1361 2553 3147 3743 4252 4848 20 20 613 919 1225 919 1455 1989 1225 2526 3138 3675 4288 4824 22 22 557 835 1114 835 1949 1114 2506 3063 3619 4176 4733 24 24 510 766 1147 766 1405 1978 1021 2489 3126 3700 4210 4786 30 30 510 817 1021 613 817 32 32 478 766 957 574 1054 34 34 450 721 901 540 992 36 36 425 681 851 510 1021 42 42 583 729 438 875 - 1 in (inch) = 25.4 mm

- 1 psi (lb/in2) = 6,894.8 Pa (N/m2) = 6.895x10-2 bar

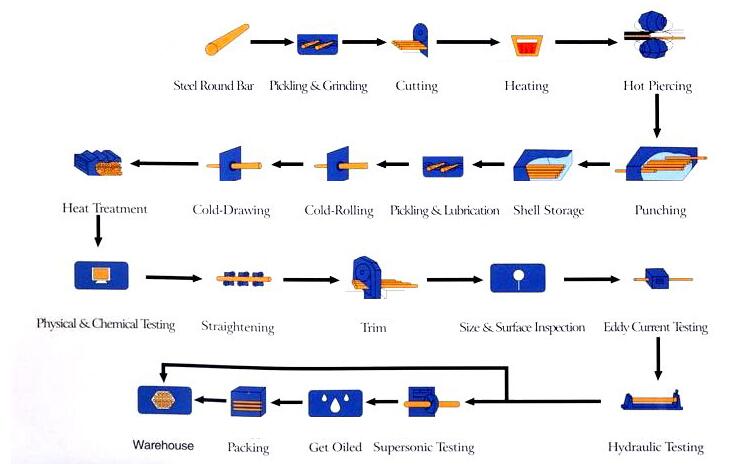

Production process