LSAW Carbon Steel Pipe

-

Introduction

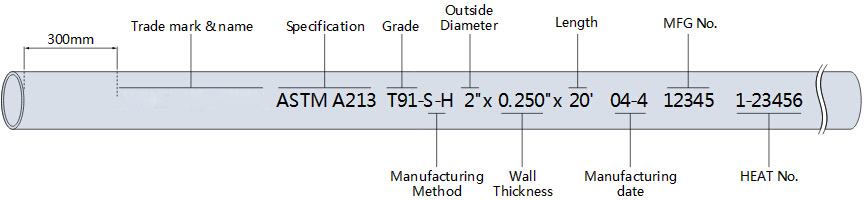

- Pipe Type:LSAW Steel Pipe,Longitudinally Submerged Arc Welding Pipe ,DSAW Steel Pipe,Welded Steel Pipe

Specification: Outside Diameter:355.6mm-2320mm

Wall Thickness:5.0mm-60mm

LENGTH:5.8m/6m/11.8m/12m/18m/32m

Standard & Grade: ASTM A53: Gr.A, Gr.B;API 5L:Gr.A,Gr.B,X42,X46, X52,X56,X60,X65 PSL1 and PSL2; ASTM A572 Gr.50;ASTM A252 ; API 5CT, ASTM 53, EN10217, DIN 2458. IS 3589, GB/T3091, GB/T9711,etc

End: Square Ends/Plain Ends (straight cut, saw cut, torch cut),Beveled/Threaded Ends

Steel Grade: API 5L: GR B, X42, X46, X56, X60, X65, X70 ASTM A53: GR A, GR B, GR C

Surface: Black Painting/Oil Painting/Anti-Rust oil/Anti-Corrosive Coating

Process: LSAW – UO(UOE)、RB(RBE)、JCO(JCOE,COE) DSAW -Double Submerged arc welded

Usage: Used for low pressure liquid delivery, such as water, gas, and oil.

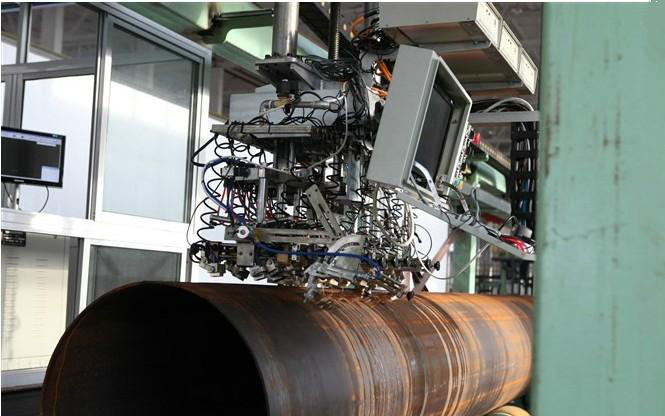

The UOE mill features the most advanced technology and process, achieves high production efficiency, stable product quality and is equipped with complete inspection equipments. UOE mill adopts U & O forming, the formed pipes are welded inside through five internal welding stations with three wires, and welded outside through four external welding stations with three wires. In accordance with different requirements of the customers, the welded pipe can be expanded either by mechanical or hydrostatic expander to improve dimensional accuracy, and eliminate residual stress.

JCOE LSAW steel pipe:

Specifications:

Outside Diameter:Φ406mm- 1626mm (16" - 64" )

Wall Thickness:6.0- 75mm (1/4" - 3" )

Quality Standards:API、DNV、ISO、DEP、EN、ASTM、DIN、BS、JIS、GB、CSA

Length:3-12.5m ( 10'- 41' )

Grades:API 5L A-X100, GB/T9711 L190-L690

This is large diameter longitudinal submerged arc welded (SAWL) pipe production line in China. The mill adopts progressive bending process, featuring evenly distributed forming stress, high uniformity of dimension, infinite sizes variation&wide poduct range, and high flexibility, etc.

Specification

-

Standard

ASTM A53 Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless API 5L Specification for Line Pipe(Two levels PSL 1 and PSL 2 of seamless and welded steel pipes for use in pipeline transportation systems in the petroleum and natural gas industries.) A252 Standard Specification for Welded and Seamless Steel Pipe Piles A500 Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes A139 Standard Specification for Electric-Fusion (Arc)-Welded Steel Pipe (NPS 4 and Over) A672 Specification for Electric-Fusion-Welded Steel Pipe for High-Pressure Service at Moderate Temperatures A691 Specification for Carbon and Alloy Steel Pipe, Electric-Fusion-Welded for High-Pressure Service at High Temperatures Specification

Outside Diameter(O.D.) Wall Thickness (W.T.) Length(m) Inch mm Min.Yield Strength(Mpa) Inch mm GR.B X42 X52 X60 X65 X70 X80 16 406 6.0-14.0 6.0-13.0 6.0-12.0 6.0-11.0 6.0-10.5 6.0-10.0 6.0-9.0 6.0-32 18 457 6.0-15.0 6.0-14.0 6.0-13.0 6.0-12.0 6.0-11.5 6.0-11.0 6.0-10.0 6.0-32 20 508 6.0-16.0 6.0-15.0 6.0-14.0 6.0-13.0 6.0-12.5 6.0-12.0 6.0-11.0 6.0-32 22 559 6.0-17.0 6.0-16.0 6.0-15.0 6.0-14.0 6.0-13.5 6.0-13.0 6.0-12.0 6.0-32 24 610 6.0-18.0 6.0-17.0 6.0-16.0 6.0-15.0 6.0-14.5 6.0-14.0 6.0-13.0 6.0-32 26 660 6.0-19.0 6.0-18.0 6.0-17.0 6.0-16.0 6.0-15.0 6.0-15.0 6.0-14.0 6.0-32 28 711 6.0-20.0 6.0-19.0 6.0-18.0 6.0-17.0 6.0-16.5 6.0-16.0 6.0-15.0 6.0-32 30 762 7.0-21.0 7.0-20.0 7.0-19.0 7.0-18.0 7.0-17.5 7.0-17.0 7.0-16.0 6.0-32 32 813 7.0-22.0 7.0-21.0 7.0-20.0 7.0-19.0 7.0-18.5 7.0-18.0 7.0-17.0 6.0-32 34 864 7.0-23.0 7.0-22.0 7.0-21.0 7.0-20.0 7.0-19.5 7.0-19.0 7.0-18.0 6.0-32 36 914 8.0-24.0 8.0-23.0 8.0-22.0 8.0-21.0 8.0-20.5 8.0-20.0 8.0-19.0 6.0-32 38 965 8.0-25.0 8.0-24.0 8.0-23.0 8.0-22.0 8.0-21.5 8.0-21.0 8.0-20.0 6.0-32 40 1016 8.0-26.0 8.0-25.0 8.0-24.0 8.0-23.0 8.0-22.5 8.0-22.0 8.0-21.0 6.0-32 42 1067 8.0-26.0 8.0-25.0 8.0-24.0 8.0-23.0 8.0-22.5 8.0-22.0 8.0-21.0 6.0-32 44 1118 9.0-27.0 9.0-26.0 9.0-24.5 9.0-23.5 9.0-22.8 9.0-22.0 9.0-21.0 6.0-32 46 1168 9.0-27.0 9.0-26.0 9.0-24.0 9.0-23.5 9.0-22.8 9.0-22.0 9.0-21.0 6.0-32 48 1219 9.0-28.0 9.0-27.0 9.0-25.4 9.0-24.0 9.0-23.5 9.0-23.0 9.0-22.0 6.0-32 52 1321 9.0-28.0 9.0-27.0 9.0-25.4 9.0-24.2 9.0-23.5 9.0-23.0 9.0-22.0 6.0-32 56 1422 10.0-29.0 10.0-28.0 10.0-26.0 10.0-24.5 10.0-23.8 10.0-23.0 10.0-22.0 6.0-32 60 1524 10.0-29.0 10.0-28.0 10.0-26.0 10.0-24.5 10.0-23.8 10.0-23.0 10.0-22.0 6.0-32 64 1626 10.0-30.0 10.0-29.0 10.0-27.0 10.0-25.4 10.0-24.8 10.0-24.0 10.0-23.0 6.0-32 68 1727 10.0-30.0 10.0-29.0 10.0-27.0 10.0-25.4 10.0-24.8 10.0-24.0 10.0-23.0 6.0-32 72 1829 10.0-30.0 10.0-29.0 10.0-27.0 10.0-25.4 10.0-24.8 10.0-24.0 10.0-23.0 6.0-32 Tolerance of Outside Diameter and Wall Thickness

Types Standard SY/T5040-2000 SY/T5037-2000 SY/T9711.1-1977 ASTM A252 AWWA C200-97 API 5L PSL1 Tube end OD deviation ±0.5%D ±0.5%D -0.79mm~+2.38mm <±0.1%T <±0.1%T ±1.6mm Wall thickness ±10.0%T D<508mm, ±12.5%T -8%T~+19.5%T <-12.5%T -8%T~+19.5%T 5.0mm<t<15.0mm, ±0.11<="" p="" style="padding: 0px; margin: 0px;"></t<15.0mm,> D>508mm, ±10.0%T T≥15.0mm, ±1.5mm Chemical Composition and Mechanical Properties

Standard Grade Chemical Composition(max)% Mechanical Properties(min) C Mn Si S P Yield Strength(Mpa) Tensile Strength(Mpa) GB/T700-2006 A 0.22 1.4 0.35 0.050 0.045 235 370 B 0.2 1.4 0.35 0.045 0.045 235 370 C 0.17 1.4 0.35 0.040 0.040 235 370 D 0.17 1.4 0.35 0.035 0.035 235 370 GB/T1591-2009 A 0.2 1.7 0.5 0.035 0.035 345 470 B 0.2 1.7 0.5 0.030 0.030 345 470 C 0.2 1.7 0.5 0.030 0.030 345 470 BS En10025 S235JR 0.17 1.4 - 0.035 0.035 235 360 S275JR 0.21 1.5 - 0.035 0.035 275 410 S355JR 0.24 1.6 - 0.035 0.035 355 470 DIN 17100 ST37-2 0.2 - - 0.050 0.050 225 340 ST44-2 0.21 - - 0.050 0.050 265 410 ST52-3 0.2 1.6 0.55 0.040 0.040 345 490 JIS G3101 SS400 - - - 0.050 0.050 235 400 SS490 - - - 0.050 0.050 275 490 API 5L PSL1 A 0.22 0.9 - 0.03 0.03 210 335 B 0.26 1.2 - 0.03 0.03 245 415 X42 0.26 1.3 - 0.03 0.03 290 415 X46 0.26 1.4 - 0.03 0.03 320 435 X52 0.26 1.4 - 0.03 0.03 360 460 X56 0.26 1.1 - 0.03 0.03 390 490 X60 0.26 1.4 - 0.03 0.03 415 520 X65 0.26 1.45 - 0.03 0.03 450 535 X70 0.26 1.65 - 0.03 0.03 585 570

Production Process

- Chemical Component Analysis

-Mechanical Properties – Elongation, Yield Strength, Ultimate Tensile Strength

-Technical Properties – DWT Test, Impact Test, Blow Test, Flattening Test

-X-ray Test

-Exterior Size Inspection

-Hydrostatic Test

-UT Test

Packaging pictures

-