SSAW Carbon steel pipe

-

Introduction

- Pipe Type:SSAW Pipe,Spirally Submerged Arc Welding Pipe ,SAWH Pipe, Sprial Steel Pipe,Piling Structure SSAW PipeSpecification: Outer diameter:219mm-4064mm

Wall thickness: 3.2mm-40mm

LENGTH:5.8/6/11.8/12/18/32meters

Standard & Grade:ASTM A53: Gr.A, Gr.B;API 5L:Gr.A,Gr.B,X42,X46, X52,X56,X60,X65 PSL1 and PSL2; ASTM A252, ASTM A500, JIS G3466, AN/NZS 1163, AN NZS1074, EN10219, EN10217 and etc.

End: Square Ends/Plain Ends (straight cut, saw cut, torch cut),Beveled/Threaded Ends

Surface: Black Painting/Oil Painting/Anti-Rust oil/Anti-Corrosive Coating

Application: Oil and gas pipeline, water transmission, liquid transportation, Building construction, Steel structure construction, Offshore/Onshore construction, Piling works, Electricity, Heating power and etc

Usage: Used for Oil and gas pipeline, water transmission, liquid transportation, Building construction, Steel structure construction, Offshore/Onshore construction, Piling works, Electricity, Heating power and etc

Test:Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Blow Test, Impact Test), Exterior Size Inspection, Hydrostatic Test, X-ray Test.

Process:

SSAW: Spiral Submerged-arc Welded

Quality Standard:

IS: 3589 Steel tubes for water and sewage

IS : 1978-1982:Steel tubes for use in transportation of oil; gas & Petroleum products

ASTM A53 Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

DIN 2458 WELDED STEEL PIPES AND TUBES

EN10217 Welded steel tubes for pressure purposes. Technical delivery conditions. Non-alloy steel tubes with specified room temperature properties

API 5L Line Pipe

SY/T5037 Spiral submerged arc-welded steel pipe for pipelines for low pressure field fluid service

SY/T 5040 Spiral submerged arc-welded steel pipe piles

CJ/T 3022 Spiral submerged-arc welded steel pipe for municipal heat supply

IS : 1978 Steel tubes for use in transportation of oil; gas & Petroleum products

ASTM A252 WELDED AND SEAMLESS STEEL PIPE PILES

Coating Standard:

ANSI/AWWA C104/A21.4 American National Standard for Cement-Mortar Lining for Ductile-Iron Pipe and Fittings for Water

ISO 21809 Petroleum and natural gas industries — External coatings for buried or submerged pipelines used in pipeline transportation systems

DIN 30670 Polyethylen coatings of steel pipes and fittings

Steel Grade:

EN: S235JR,S235J0, S235J2, S275JR,S275J0, S355JR, S355J0,S355J2H,S460,S690,

DIN: St12, St13, St14, St33, St37, St44, ST52

ASTM A 53: Gr. A, Gr B, Gr C, Gr.D

API 5L: A, B, X42, X46, X52, X56, X60, X65 X70

GB/T9711: L175, L210, L245, L290, L320, L360, L290, L320, L360, L390, L415, L450, L485, L555

Specification

- Sizes:Chemical Analysis and Mechanical Properties of SSAW Steel Pipe

Standard Grade Chemical Composition(max)% Mechanical Properties(min) C Si Mn P S Tensile Strength(Mpa) Yield Strength(Mpa) API 5L PSL1 A 0.22 - 0.90 0.030 0.030 335 335 B 0.26 - 1.20 0.030 0.030 415 415 X42 0.26 - 1.30 0.030 0.030 415 415 X46 0.26 - 1.40 0.030 0.030 435 435 X52 0.26 - 1.40 0.030 0.030 460 460 X56 0.26 - 1.40 0.030 0.030 490 490 X60 0.26 - 1.40 0.030 0.030 520 520 X65 0.26 - 1.45 0.030 0.030 535 535 X70 0.26 - 1.65 0.030 0.030 570 570 API 5L PSL2 B 0.22 0.45 1.20 0.025 0.015 415 415 X42 0.22 0.45 1.30 0.025 0.015 415 415 X46 0.22 0.45 1.40 0.025 0.015 435 435 X52 0.22 0.45 1.40 0.025 0.015 460 460 X56 0.22 0.45 1.40 0.025 0.015 490 490 X60 0.12 0.45 1.60 0.025 0.015 520 520 X65 0.12 0.45 1.60 0.025 0.015 535 535 X70 0.12 0.45 1.70 0.025 0.015 570 570 X80 0.12 0.45 1.85 0.025 0.015 625 625 ASTM A53 A 0.25 0.10 0.95 0.050 0.045 330 330 B 0.30 0.10 1.20 0.050 0.045 415 415 ASTM A252 1 - - - 0.050 - 345 345 2 - - - 0.050 - 414 414 3 - - - 0.050 - 455 455 EN10217-1 P195TR1 0.13 0.35 0.70 0.025 0.020 320 320 P195TR2 0.13 0.35 0.70 0.025 0.020 320 320 P235TR1 0.16 0.35 1.20 0.025 0.020 360 360 P235TR2 0.16 0.35 1.20 0.025 0.020 360 360 P265TR1 0.20 0.40 1.40 0.025 0.020 410 410 P265TR2 0.20 0.40 1.40 0.025 0.020 410 410 EN10217-2 P195GH 0.13 0.35 0.70 0.025 0.020 320 320 P235GH 0.16 0.35 1.20 0.025 0.020 360 360 P265GH 0.20 0.40 1.40 0.025 0.020 410 410 EN10217-5 P235GH 0.16 0.35 1.20 0.025 0.020 360 360 P265GH 0.20 0.40 1.40 0.025 0.020 410 410 EN10219-1 S235JRH 0.17 - 1.40 0.040 0.040 360 360 S275JOH 0.20 - 1.50 0.035 0.035 410 410 S275J2H 0.20 - 1.50 0.030 0.030 410 410 S355JOH 0.22 0.55 1.60 0.035 0.035 470 470 S355J2H 0.22 0.55 1.60 0.030 0.030 470 470 S355K2H 0.22 0.55 1.60 0.030 0.030 470 470 Standard and Classfication

Classfication Standard Main Products Steel Pipe for Fluid Service GB/T 14291 Welded pipe for mine fluid sevice GB/T 3091 Welded pipe for low pressure fluid service SY/T 5037 Spirally submerged arc welded steel pipe for pipelines for low pressure fluid service ASTM A53 Black and hot-hipped galvanized welded and seamless steel pipe BS EN10217-2 Welded steel tybes for pressure purposes – delivery technical conditions – part2: Electric welded non- alloy and alloy steel tubes with specified elevated temperature properties BS EN10217-5 Welded steel tybes for pressure purposes – delivery technical conditions – part5: submerged arc welded non-alloy and alloy steel tubes with specified elevated temperature properties Steel Pipe for Ordinary Structure GB/T 13793 Longitudinally electric resistance welded steel pipe SY/T 5040 Spirally submerged arc welded steel pipe piles ASTM A252 Welded and seamless steel pipe piles BS EN10219-1 Cold formed welded structural hollow sections of non-alloy and fine grain steels – part1: Technical delivert conditions BS EN10219-2 Cold formed welded structural hollow sections of non-alloy and fine grain steels – part2: tolerances dimmsions and sectional properties Line Pipe GB/T 9711.1 Steel pipe for pipeline transportation system of petroleum and natural gas industries(Class A steel pipe) GB/T 9711.2 Steel pipe for pipeline transportation system of petroleum and natural gas industries(Class B steel pipe) API 5L PSL1/2 Line pipe Casing API 5CT Steel pipe for use as casing or tubing for wells of petroleum and natural gas industries Tolerance of Outside Diameter and Wall Thickness of SSAW Steel Pipe

Standard Tolerance of Pipe Body Tolerance of Pipe End Tolerance of Wall Thickness Out Diameter Tolerance Out Diameter Tolerance GB/T3091 OD≤48.3mm ≤±0.5 OD≤48.3mm – ≤±10% 48.3 ≤219mm ≤±1.0% 48.3

≤273.1mm– 219 ≤508mm ≤±0.75% 219

≤508mm-0.8~+2.4 OD>508mm ≤±1.0% OD>508mm -0.8~+3.2 GB/T9711.1 OD≤48.3mm -0.79~+0.41 – – OD≤73 -12.5%~+20% 60.3 ≤457mm ≤±0.75% OD≤219mm -0.4~+1.59 88.9≤OD≤457 -12.5%~+15% 508 ≤941mm ≤±1.0% OD≥323.9 -0.79~+2.38 OD≥508 -10.0%~+17.5% OD>941mm ≤±1.0% – – – – GB/T9711.2 60 ≤610mm ±0.75%D~±3mm 60 ≤610mm ±0.5%D~±1.6mm 4mm ±12.5%T~±15.0%T 610 ≤1430mm ±0.5%D~±4mm 610 ≤1430mm ±0.5%D~±1.6mm WT≥25mm -3.00mm~+3.75mm OD>1430mm – OD>1430mm – – -10.0%~+17.5% SY/T5037 OD<508mm ≤±0.75% OD<508mm ≤±0.75% OD<508mm ≤±12.5% OD≥508mm ≤±1.00% OD≥508mm ≤±0.50% OD≥508mm ≤±10.0% API 5L PSL1/PSL2 OD<60.3 -0.8mm~+0.4mm OD≤168.3 -0.4mm~+1.6mm WT≤5.0 ≤±0.5 60.3≤OD≤168.3 ≤±0.75% 168.3 ≤610 ≤±1.6mm 5.0 ≤±0.1T 168.3 ≤610 ≤±0.75% 610 ≤1422 ≤±1.6mm T≥15.0 ≤±1.5 610 ≤1422 ≤±4.0mm OD>1422 – – – OD>1422 – – – – – API 5CT OD<114.3 ≤±0.79mm OD<114.3 ≤±0.79mm ≤-12.5% OD≥114.3 -0.5%~1.0% OD≥114.3 -0.5%~1.0% ≤-12.5% ASTM A53 ≤±1.0% ≤±1.0% ≤-12.5% ASTM A252 ≤±1.0% ≤±1.0% ≤-12.5%

Production process

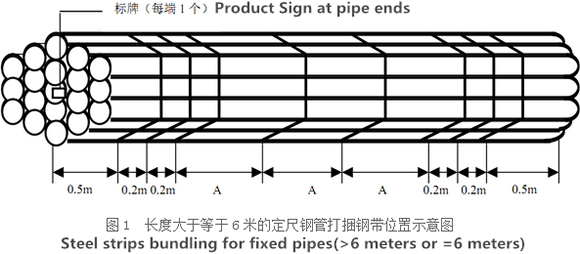

Packaging pictures