U Tube

Introduction

Pipe Type:U Shape Steel Bending Tube Stainless Steel Tube/Pipe Bending U Tube

Products Details

| Available U-bent Tubes | ||||||

| Products | Dimensions (mm) O.D. |

W.T. | Length | Standards | Materials | Remarks |

| U-bent Tubes for Heat Exchanger |

12.7-76.2mm (1/2"-3") |

0.5-5.16mm (0.02"-0.203") |

Leg Length: 15.24m(50') Total length: 32.00m(105') |

ASTM/ASME A/SA213 |

T5,T11,T12,T22, T9,T91, TP304/304L, TP304H, TP316/316L, TP347/347H, TP316Ti, TP321/321H, TP310S |

Seamless ferritic and Austenitic Stainless Steel U-bent Tubes |

| ASTM/ASME A/SA249 |

TP304,TP304L, TP316,TP316L... |

Welded Stainless Steel U-bent Tubes |

||||

| ASTM/ASME A/SA789 |

UNS S31803/32205, UNS S32750... |

Duplex Stainless Steel U-bent Tubes |

||||

| ASTM/ASME A/SA163 |

Monel400, UNS N06600,625, Incoloy800/800H, 825... |

Ferritic and Martensitic Stainless Steel Seamless U-bent Tubes |

||||

| Seamless and (Welded) Re-drawn Stainless Steel Feed Water Heater U-bent Tubes |

12.7-25.4mm (1/2"-1") |

0.7-3.05mm (0.028"-0.12") |

Leg Length: 15.24m(50') Total length: 32.00m(105') |

ASTM/ASME A/SA688/213 ASTM/ASME A/SA803 |

TP304,TP304L, TP304LN, TP316,TP316L. TP316LN,TP439... |

Feed Water Heater Tubes for Thermal Power Station |

-

Specification

-

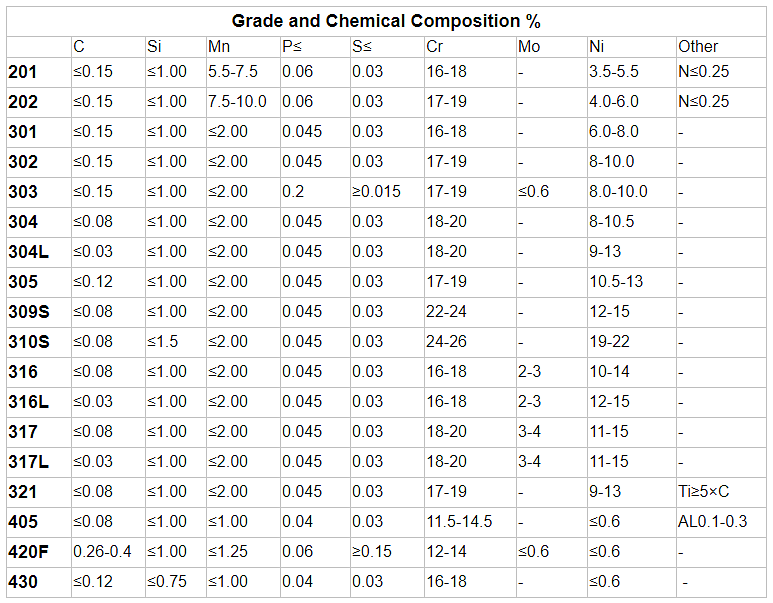

Chemical Composition

Elem-Ent Grade TP304 TP304L TP304LN TP316 TP316L TP316LN TP XM-29 TP 304N TP 316N % UNS S30400 S30403 S30453 S31600 S31603 S31653 S24000 S30451 S31651 C, Max 0.08 0.035 0.035 0.08 0.035 0.035 0.060 0.08 0.08 Mn, Max 2.00 2.00 2.00 2.00 2.00 2.00 11.50-14.50 2.00 2.00 Ph, Max 0.040 0.040 0.040 0.040 0.040 0.040 0.060 0.040 0.040 S, Max 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 Si,,Max 0.75 0.75 0.75 0.75 0.75 0.75 1.00 0.75 0.75 Ni 8.00-11.00 8.00-13.00 8.00-13.00 10.00-14.00 10.00-15.00 10.00-15.00 2.25-3.75 8.00-1.00 10.00-14.00 Cr 18.00-20.00 18.00-20.00 18.00-20.00 16.00-18.00 16.00-18.00 16.00-18.00 17.00-19.00 18.00-20.00 16.00-18.00 Mo - - - 2.00-3.00 2.00-3.00 2.00-3.00 - - 2.00-3.00 N - - 0.10-0.16 - - 0.10-0.16 0.20-0.40 0.10-0.16 0.10-0.16

Dimensional Tolerance

ASTM A688 U bend tube tolerance of outside should be accordance with specification A1016/M, bent portion of U tubes for R =2 X D or greater, tolerance shall deviate from the nominal diameter prior to bending by more than 10 %, if less than 2 X D is specified, tolerances could be greater, minimum wall thickness shall not exceed +20 % − 0, average wall thickness are 10 % of the nominal wall thickness, bent area wall tolerance shall not be less than value determined by the equation: 4RT/(4R+D).

Tube Leg Length Tolerance

Leg Length, Ft (M) Plus Tolerance, In (Mm) <= 20 (6) 1/8 (3.2) >20(6), <=30(9) 5/32 (4.0) >30 (9), <=40 (12.2) 3/16 (4.8) Squareness Of Ends Tolerance

Tube OD, In, (Mm) Tolerance, In, (Mm) <=5.8 (15.9) 0.010 (0.25) >5.8 (15.9), <=1 (25.4) 0.016 (0.4) Compared to ASTM A249/A268 specification, ASTM A688 requires more and specific tests to ensure high quality tube, and more tighter tolerances.

Testing & Inspection

- Tensile Strength

- Reverse bending test

- Flattening test

- Flare test

- Flange test

- Dimensional

- Hydrostatic Test

- Pneumatic Test

- Hardness

- Eddy Current test

- Intergranular Corrosion (option)